Xinying Environmental Technology (Hubei) Co., Ltd. (referred to as Xinying Technology) is located in the Nonferrous Industrial Park of Huangjinshan Development Zone, Huangshi City, Hubei Province.

The leading products developed and produced by Xinying Technology include laminated high-frequency vibrating fine screens, anti blocking and wear-resistant polyester screens.

Stay informed of the latest news from Xinying Technology and we will be dedicated to serving you!

Strive to digitize the mining and beneficiation industry and achieve the great goal of "China's equipment, equipment for the world"!

Xinying Technology will adhere to the principle of "Technological upgrade, customer first, lifelong service" and take the company's listing and standardized operation as an opportunity.

磨矿分级作业是选矿生产中极为重要的工艺环节,其中处理能力事关选厂的产能和选矿成本,溢流产品中矿石粒级分布决定后续选别指标的好坏。

依靠人工调整磨矿分级作业不能充分提高磨机的处理能力,也不能保证分级后溢流产品的合格率以及粒级分布达到最佳。尤其在矿石性质(硬度、粒度、结晶水等)多变时,生产作业指标波动较大。精细分级作业与智能化磨矿相结合产生的效益是其他模式无法比拟的,对磨矿分级工作具有极重要的意义。

【应用领域】有色金属、黑色金属、非金属矿山选矿厂

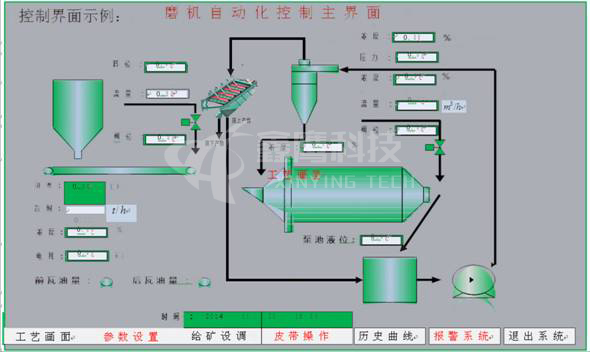

【设备配置】球磨机、高频振动细筛、三分旋流器

[Process Details]

1. Current situation at home and abroad

Intelligent control is fully considered in the design process of every beneficiation plant abroad, especially in grinding and grading operations. For example, in a copper beneficiation plant in Canada with a processing capacity of 3000Mt/a and only about 200 employees, the per capita annual labor productivity far exceeds that of our country's beneficiation plants, especially in mining developed countries such as the UK, Australia, and Sweden.

However, in China, few beneficiation plants designed and put into operation before the 1980s have paid attention to the application of fine and intelligent grading technology, mainly because large-scale fine grading equipment, control components, and control theory cannot be accurately applied to the field of grinding and grading. Hubei Xinying Environmental Protection Technology Co., Ltd. has conducted extensive and effective research and application on the intelligent fine grading control system for grinding and grading, achieving satisfactory results.

2. Control purpose and economic benefit analysis

(1) Control purpose

The following control objectives can be achieved according to different user requirements:

a、 On the premise of meeting the on-site process requirements with a stable graded overflow particle size qualification rate, the improved processing capacity per unit time is achieved.

b、 On the premise of stabilizing the processing capacity of the grinding machine, improve the qualification rate of graded overflow particle size.

c、 Simultaneously improve the processing capacity of the grinding machine and the qualification rate of graded overflow particle size.

d、 Simultaneously improving the processing capacity of the grinding machine and the qualification rate of the graded overflow particle size, while increasing the proportion of good particle size content.

e、 Under the premise of stabilizing the processing capacity of the grinding machine and achieving a qualified rate of graded overflow particle size, optimize the water supply (sand return water, ore discharge water).

(2) Economic benefit analysis

On the premise of meeting and stabilizing the grading granularity requirements, increase the processing capacity by 15-20%. Taking Ø 2736 ball mill as an example, the annual direct benefit is nearly one million. At the same time, intelligent refined control systems can reduce the labor intensity of workers, decrease equipment failure rates, significantly improve labor productivity and equipment operation rates, and have special significance for improving the output and quality of beneficiation products. Therefore, intelligent refined grading control systems have become a trend in the development of the mineral processing industry to control production.

[Technological advantages]

a、 On the premise of meeting the on-site process requirements with a stable graded overflow particle size qualification rate, the improved processing capacity per unit time is achieved.

b、 On the premise of stabilizing the processing capacity of the grinding machine, improve the qualification rate of graded overflow particle size.

c、 Simultaneously improve the processing capacity of the grinding machine and the qualification rate of graded overflow particle size.

d、 Under the premise of stabilizing the processing capacity of the grinding machine and achieving a qualified rate of graded overflow particle size, optimize the water supply (sand return water, ore discharge water).

Intelligent Control Center